Groundbreaking Life Cycle Assessment of pulse ingredients helps meet consumer demands for more sustainable foods and beverages

This week in Barcelona, Jannatul Ferdous, a researcher at the University of British Columbia Food Systems PRISM (Priority Research for Integrated Sustainability Management) Lab, presented the first ever Life Cycle Assessment of Processed Pea, Lentil, and Bean Products in Canada at the 14th LCA Food International Conference. James Del Frari, VP, Operations at Avena Foods, provided data to Jannatul and was included as second author.

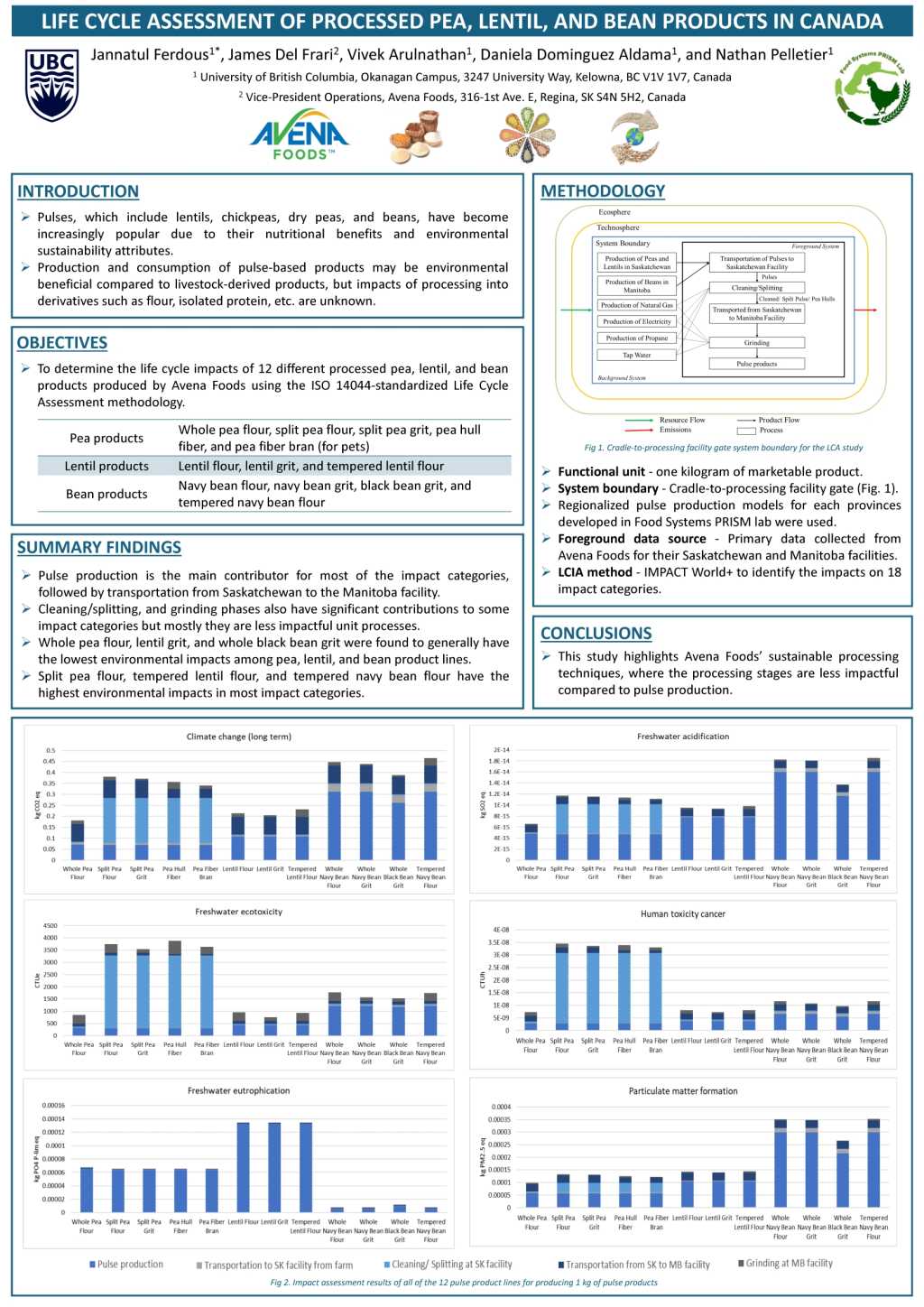

This was part of a larger PRISM Lab report that quantified the life cycle impacts per kilogram of greenhouse gas emissions for 17 Avena pulse and oat ingredients – Life Cycle Assessment of Avena Foods pulse and oat product lines and estimation of Scope 1 and Scope 2 GHG emissions at Avena Foods facilities in Saskatchewan and Manitoba. ISO 14044-standardized Life Cycle Assessment methodology used reviews 15 impact categories¹.

Poster presented at the 14th LCA Food International Conference, September 2024, Barcelona, Spain.

What is a Life Cycle Assessment?

Life Cycle Assessment (LCA) is a useful tool in quantifying the environmental impact of food and beverage ingredients. The LCA is calculated throughout the life of the ingredient from ‘cradle to gate’.

The parameters of the LCA include all inputs, outputs and emissions associated with all stages in the evolution of the products, from the extraction of raw materials to the production and treatment of the crops, and processing into final products.

LCA is expressed as the number of kilograms CO2 equivalency per kilogram or kg CO2e/kg. This equation is based on mass balance.

What did we learn from the LCAs of Avena’s ingredients?

The greatest impacts on LCA scores are from the farm production of the pulses or oats, the transportation of grain, and the cleaning and grinding of the raw materials.

However, the PRISM LCA report did demonstrate that Avena’s sustainable processing techniques have a lower environmental impact when compared to other typical pulse processing systems.

In terms of specific ingredients, whole pea flour, lentil grit and whole black bean grit have the lowest environmental impact. Split pea flour, specialty milled ready to eat functional lentil and navy bean flours are slightly higher. Among Avena’s oat lines, steel cuts had the lowest carbon footprint across most impact categories, though the difference was not significant.

Yellow pea flour

Pulse grit

How can manufacturers benefit from LCAs?

Consumers are demanding foods and beverages that are more sustainable. The LCA of a product is quantifiable data that may be used by companies to communicate the environmental impact of their products and neutralize the threat of being accused of ‘green washing’.

In addition, knowing the LCA of ingredients provides advantages to food and beverage manufacturers as they navigate complex supply chains.

LCA’s are:

- Helping research and development professionals as they work to create more sustainable products.

- Informing procurement in their evaluation of suppliers as they make purchasing decisions.

- Giving companies a competitive advantage in the market where consumers are using their purchasing power to encourage more sustainable manufacturing.

- Supporting management in making informed strategic choices around on-target sustainability initiatives, and thereby reducing risk.

Avena partners with food and beverage processors to help them in calculating the LCA of food and beverage products.

Let us know how we may support you in your sustainability goals!

Contact us to meet your LCA and sustainability goals!

contact us today

Partnering for safe, healthy diets and a sustainable world.

Footnote citations:

- Climate change, fossil and nuclear energy use, freshwater acidification, ecotoxicity, eutrophication, human toxicity (both cancer and noncancer) ionizing radiations, land occupation and transformation and marine eutrophication.